In recent years, nanofibers and nanofiber materials have gained increasing attention for their role in combating the global pandemic, as they have been used in the most advanced face masks. However, nanofiber technology has many applications that can improve our lives in various ways. In this article, we will explore the history of nanofibers, their properties, and their uses in different fields. We will also recommend some amazing products with nanofiber technology that you can try right now!

What is Nanofiber?

Nanofiber is an extremely small and lightweight fiber with a diameter that ranges from tens of nanometers to one micrometer. To put this into perspective, a human hair has a diameter of around 75,000 nanometers, so nanofiber is very tiny. In fact, a little more than one gram of nanofiber would be enough to wrap around the Earth's equator, a distance of 40,000 kilometers. Nanofibers have unique properties that make them useful in a wide range of fields, including medicine, cosmetics, the textile industry, and filtering and purification.

Some of the Basic Properties of Nanofiber Materials Are:

- High porosity,

- large volume of pores,

- low density,

- good breathability,

- large specific surface area.

Nanofiber materials can be easily combined with other materials, making them versatile and useful in a wide range of applications. These properties make nanofiber materials valuable in industries such as textiles, health care, energy storage, and more.

Nanofiber Technology: A Game-changer for Health Protection and Treatment

Nanofiber technology has opened up new frontiers in health protection and treatment, offering possibilities that were previously unimaginable. In recent years, it has become an indispensable part of preventing covid-19. The pores between the fibers are so tiny (with dimensions of only about 20-100 nm) that viruses, bacteria, or allergens have no chance of penetration.

Compared to regular face masks, FFP2 respirators with a nanofiber membrane offer superior protection and breathability.

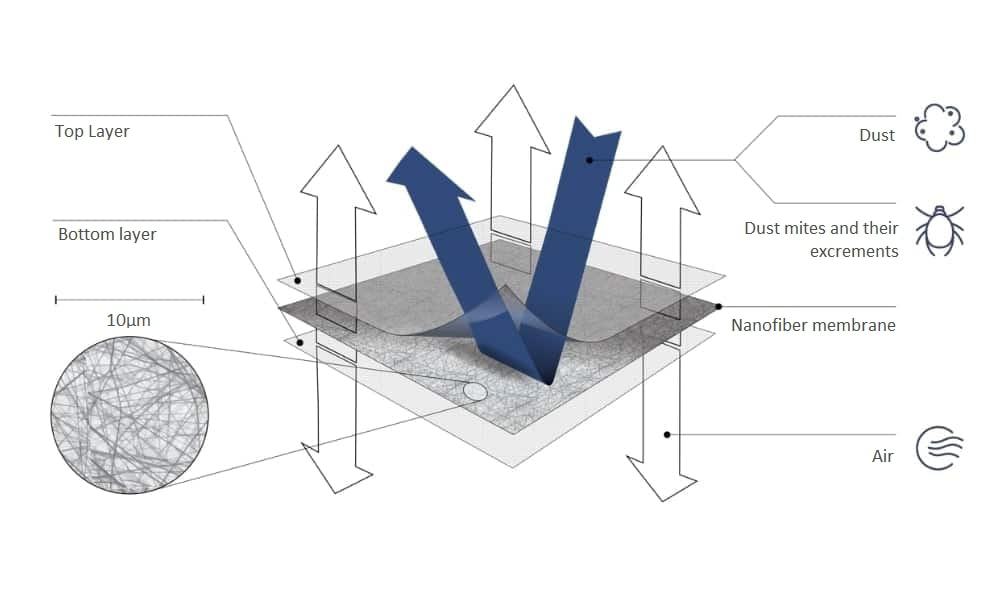

The same applies to anti allergy bedding with a nanofiber membrane, which prevents dust mites and their allergens from causing any inconvenience to your life and sleep.

Nanofiber Technology as an Effective Tool in Air Purification

Nanofiber membrane technology has proven to be an effective tool in air purification. The tiny pores within the membrane allow it to effectively capture and filter a wide range of particles and contaminants from the air, including allergens, bacteria, and viruses. This makes it an ideal choice for air purifiers, as well as other applications such as air filtration systems in hospitals and other sensitive environments. In addition to its effectiveness, nanofiber membrane technology is also highly durable and easy to clean, making it a convenient and long-lasting solution for air purification.

Nanofiber Technology for Wound Healing

Nanofiber technology has the potential to revolutionize the way we treat injuries and promote healing. One of the most promising applications of this technology is in the development of bandages and wound dressings. These bandages are made from a porous nanofiber membrane that effectively blocks the entry of bacteria and other contaminants, while allowing the wound to "breathe" and facilitating the flow of oxygen and other nutrients necessary for healing.

In addition to their protective properties, these nanofiber bandages also promote the healing process in several ways. The high porosity of the membrane allows for the efficient removal of wound exudate, preventing the build-up of harmful substances that can slow or impede healing. The large surface area of the membrane also allows for the efficient delivery of medications and other therapeutic agents directly to the wound site.

Nanofiber technology is also being explored for use in the treatment of fungal infections, such as athlete's foot. In these applications, the high porosity and large surface area of the nanofiber membrane allow it to effectively capture and neutralize the fungal cells, while also allowing for the efficient delivery of antifungal medications.

Overall, the unique properties of nanofiber technology offer exciting possibilities for the treatment and acceleration of wound healing. With further research and development, it is likely that we will see an increasing number of applications for this technology in the medical and healthcare fields.

They are also used in tissue engineering, where they play an important role in building the "scaffolding" for tissue cell growth and the preparation of replacement organs.

Brief History of Nanofiber Technology

Nanofibers are undoubtedly a technology of the future, but don't be fooled, they have been with us for a long time.

Based on the discoveries and manuscripts of British physicist Ch. V. Boyse from 1887, which dealt with the development of nanofibers and how they could be produced, the first modern patent for electrostatic spinning was filed around 1900 by American inventors W. J. Morton and J. F. Cooley. Their ideas were revived in the early 1990s by a series of excellent articles on the spinning of many polymer materials by American D. Reneker from Akron University in Ohio, which prompted intensive research.

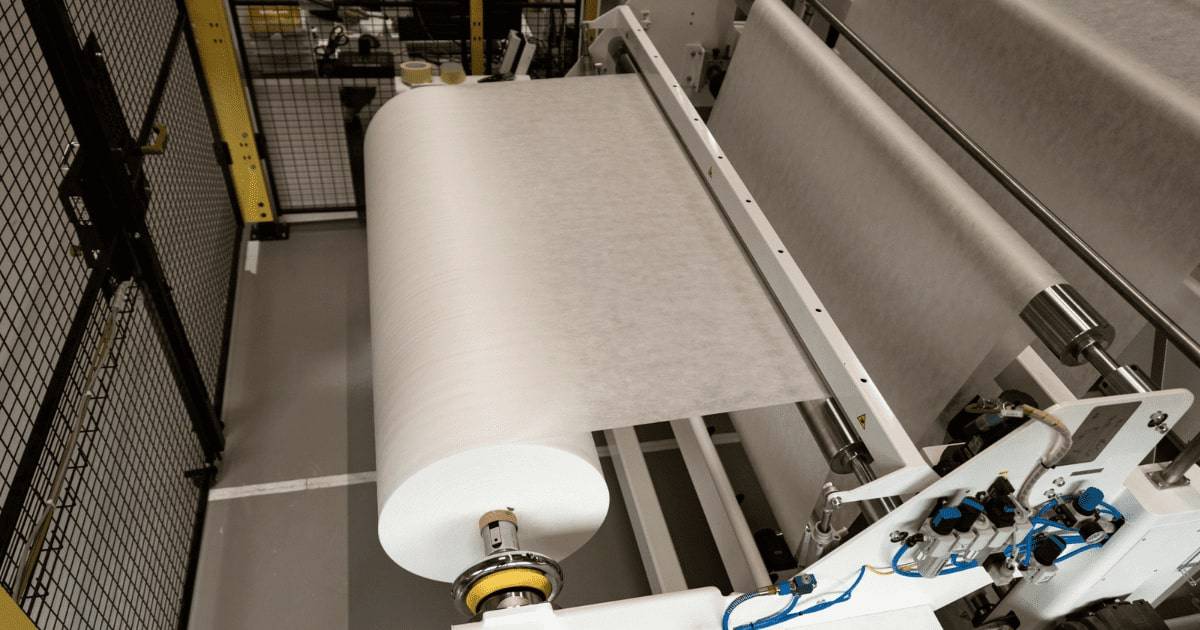

The first nanofibers were therefore able to be produced by scientists in the first half of the 20th century. However, they were limited by the technologies of the time, which did not allow them to produce large amounts of nanofibers, and it was therefore not possible to embark on industrial production. It was not until the turn of the 20th and 21st centuries that technology reached the required level, allowing the production of large quantities of nanofibers, opening the doors to the world of industry.

Want to find out who is the world's biggest nanotechnologist? Read our article on nanotechnologies.

Want to find out who is the world's biggest nanotechnologist? Read our article on nanotechnologies.

The Czech Republic is the Birthplace of Industrial Nanofiber Production

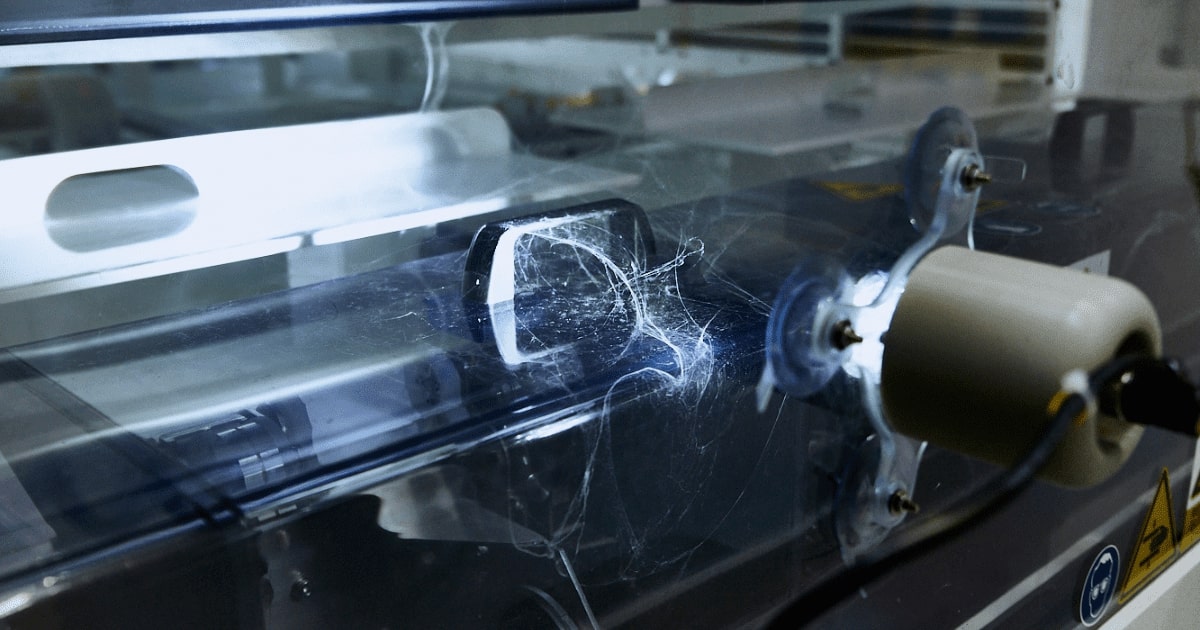

The Czech Republic is a global leader in the application of nanofiber technology. In 2003, a team led by Czech professor Oldřich Jirsák at the Technical University in Liberec developed the Nanospider™ technology, which allows for the industrial production of non-woven textiles made from nanofibers with a diameter of 20-500 nm.

Unlike previous methods, the Nanospider™ technology does not use nozzles or capillaries to create the fibers. Instead, it relies on the rotation of a cylinder in a polymer solution, which creates a thin film on the cylinder's surface. This film is then spun into nanofibers using physical phenomena.

The first Nanospider™ machine for industrial nanofiber production was released in 2005. The license for the technology is held by the Czech company Elmarco, which was the only producer of machines for the production of non-woven textiles from nanofibers in the world at the time of its release.

How Nanofibers Are Made:

Nanofibers are made from natural or synthetic materials such as cellulose, keratin, collagen, or hyaluronic acid, which is commonly found in the human body, but also from polyamide 6, PLA, polyurethane, PHB, PCL, and many other raw materials that give nanofibers their unique properties.

The starting material for the production of nanofibers is a natural or synthetic polymer, usually in the form of a polymer solution or melt. Today, there are many ways to prepare a nanofiber layer.

The most commonly used methods of producing nanofibers are:

- centrifugal spinning

- melt blown

- electrostatic spinning

- stretching

- phase separation

- pressure spinning

- hydrothermal method.

Not all of these methods are industrially viable. The most commonly used method is electrostatic spinning (electrospinning), which uses high voltage to cause a polymer solution droplet to literally shoot out a fiber. The fiber then begins to stretch and narrow in an electric field until it reaches extremely thin diameters (nano sizes), while the solvent evaporates and a solid nanofiber is formed.

The mentioned production line, Nanospider™, operates on this principle and is able to produce a large amount of high-quality nanofibers.

The newest method of nanofiber production is called hybrid spinning, which combines electrostatic, centrifugal, and pressure spinning using the Nano Hybrid Spray NT equipment from the Czech company nanoSPACE Technology. This special spinning equipment allows for the simultaneous spinning of up to 4 different spinning solutions and effectively combines different types of polymers into a single membrane.

In Which Products Can Nanofibers Be Found?

In recent years, nanofibers have finally gained their deserved place in the spotlight among the general public and can now be found in virtually all industries. They play a significant role in medicine, biotechnology, chemistry, the food and textile industries, cosmetics, and energy.

Nanofiber membranes are used in a variety of technical and medical applications due to their unique protective and filtration properties. These membranes can be found in products such as:

- Face masks with a nanofiber layer,

- anti-dust mite bedding made with nanotextile,

- air conditioning filters,

- Sleeping bags,

- mosquito nets with a nanomembrane,

- Anti-aging sheet masks,

-

and air purifiers.

Anti Dust Mite Bedding with Nanofiber

Anti-dust mite bedding with a nanofiber layer is a type of bedding that is designed to protect against dust mites, which are tiny insects that can live in fabrics and can cause allergic reactions in some people. This type of bedding is made with a special layer of nanofibers that acts as a barrier against dust mites, preventing them from getting into the bedding and coming into contact with the skin.

The use of nanofiber technology in anti-dust mite bedding has several advantages. First, the nanofiber layer is extremely thin and lightweight, so it doesn't add any significant bulk to the bedding. This makes it comfortable to sleep on and easy to wash and maintain. Second, the nanofiber layer is highly breathable, so it allows air to circulate freely and doesn't trap heat or moisture. This can help prevent overheating and sweating at night, which can exacerbate allergies and other respiratory problems.

You can buy:

- Anti allergy pillows,

- anti allergy blankets,

- anti allergy bed linen,

- anti allergy mattress, pillow, and blanket covers

Tip: Find out how to equip an allergy sufferer's bed.

#produkty#https://www.nanospace.store/for-allergy-sufferers/

Outdoor Clothing and Sleeping Bags

If you're an outdoors enthusiast and love camping, you're probably aware that the best sleeping bags and jackets are filled with high-quality goose down. However, one issue with down sleeping bags is that they can get wet and lose their insulating properties.

That's where the Czech company KWAK comes in. They've developed outdoor sleeping bags with a nanofiber membrane that makes them 100% windproof and completely water-repellent. These sleeping bags are lightweight, highly breathable, and have a water column height of 12,000 mm. In other words, they're perfect for keeping you warm and dry in the great outdoors.

Anti Aging Sheet Masks with Nanofiber Layer

Nanofibers are also an important part of the cosmetics industry, where they help active ingredients penetrate the skin more effectively. These tiny fibers act as a transport system for these ingredients, making it easier for them to enter the skin and work their magic.

Nanofibers are often used in facial masks, such as those made by the Czech company nanoBeauty. With over a decade of experience in developing nanofiber products, nanoBeauty's facial masks are designed to help the active ingredients in their products work more effectively. Other popular products that use nanofibers include under-eye masks for reducing wrinkles, such as the Nano Eye Lift from the company NAFIGATE.

The FRANAIL nail hardener is the first product in the world to use biocompatible nanofibers to carry active ingredients such as oregano and aloe vera. This Czech product uses nanofibers to strengthen and regenerate nails without causing mycoses (a fungal infection). It's also effective at strengthening and restoring nails after gel nail removal.

#produkty#https://www.nanospace.store/search/?string=%5Bn%5Dfibrecare

Cleaning Water from Microplastics

While tap water is a much better choice than bottled water, it still contains a number of substances that we don't want to drink in large quantities. Water from water purifiers flows into our households containing chlorine, pharmaceutical residues, and microplastics, which are increasingly being recognized as a global problem.

The Czech company H20 nanotec has developed an innovative water purification system that uses a unique nanofiber membrane to remove microplastics from drinking water. This membrane has pores that are only 0.1 microns in size, making it effective at filtering out microplastics of a similar size. In addition to removing microplastics, the system also filters out particles of dirt, sand, rust, and algae. Using this system can also extend the lifespan of appliances like kettles, coffee makers, and washing machines.

#produkty#https://www.nanospace.store/water-cleaning/

Is tap water healthy? Find out in the next article.

Face Masks with Nanofiber Layer

Face masks with a nanofiber layer are a type of personal protective equipment (PPE) that are designed to protect the wearer from respiratory infections and other airborne contaminants. These masks are made with a special layer of nanofibers that acts as a filter, trapping particles and microbes and preventing them from entering the airways.

One type of face mask that incorporates a nanofiber layer is the FFP2 mask, which stands for "filtering facepiece" and is rated to filter at least 94% of airborne particles. Another type is the FFP3 mask, which is rated to filter at least 99% of airborne particles. These masks are commonly used in medical settings, as well as in other industries where there is a risk of exposure to infectious diseases or other airborne contaminants.

The use of nanofiber technology in face masks has several advantages. First, the nanofiber layer is extremely thin and lightweight, so it doesn't add any significant bulk or discomfort to the mask. This makes it easy to wear for extended periods of time without causing fatigue or discomfort. Second, the nanofiber layer is highly breathable, so it allows air to circulate freely and doesn't trap heat or moisture. This can help prevent overheating and sweating, which can make it difficult to wear a mask for long periods of time.

#produkty#https://www.nanospace.store/search/?string=washable+nano+face+mask

nanoSPACE Antivirus Gaiter - nanoSPACE®

A bandana with a nanofiber layer works as FFP2 mask but it is also a versatile and convenient piece of protective gear that is perfect for use in a variety of situations. This type of bandana is made with a special layer of nanofibers that acts as a filter, trapping particles and microbes and preventing them from entering the airways.

One of the main benefits of using a bandana with a nanofiber layer is that it provides effective protection against a wide range of airborne contaminants, including dust, allergens, pollen, bacteria, and viruses. This makes it a great choice for people who suffer from allergies or asthma, as well as for anyone who wants to protect themselves during traveling.

#produkty#https://www.nanospace.store/search/?string=gaiter

Another advantage of using a bandana with a nanofiber layer is that it is easy to wear and can be adjusted to fit comfortably over the nose and mouth. This makes it perfect for use during activities like running or hiking during winter.

What Is The Future of Nanofibers?

The future of nanofibers is huge and we will probably see them in all industrial sectors. Since nanofibers can also be made from 100% natural ingredients, you can also add nanofibers to silk and herbs, their use will be more and more common in cosmetics, food industry and in medicine. The undisputed advantage of nanofibers is the zero-waste production and a much higher extraction of active ingredients.

Nanofibers have a great potential in the food industry, it is already clear that nanofibers will play a major role in the production of artificial meat. I see even greater use, for example in agriculture, where they could be used to improve fertilizer efficiency, which would save money and protect the environment.

Nanofiber membranes are already proving to be the most powerful and environmentally friendly method of air and water filtration, and they have also been successful in the textile industry, where they are used in outdoor and medical textiles.

Nanofibers are increasingly mentioned in construction, where they can be used as additives to improve material properties.

Are Nanofibers Safe?

It is natural to fear and be concerned about anything new and unknown. It is important to realize that nanofibers are much larger than, for example, nanoparticles. Their thickness is usually from 100 to 800 nanometers, and a nanofiber membrane can be observed with the naked eye.

And are they safe? It depends on the material they are made of. As we mentioned, nanofibers can be made from natural or synthetic materials. Therefore, if they are made of safe material and are firmly anchored in larger units and do not release into the environment, they cannot harm health or the environment.

In Europe, final products made from nanofibers are rigorously tested according to strict safety rules. You have nothing to be afraid of, and you can fully enjoy the excellent protection and other top-class properties they offer.

Unlock the Potential of this Revolutionary Technology and Shop the Best Products

Nanofiber technology offers a unique and effective way to protect and improve our health. Its invisible nature and incredible properties make it a valuable addition to any health and wellness routine. You should try out some of the available products that incorporate nanofiber technology, such as anti-aging sheet masks and anti-allergy bedding, to experience the benefits for themselves. Whether you are looking to prevent illness or simply improve your overall well-being, nanofiber technology is worth considering.

Sources

- LIM, Chwee Teck, et al. Nanofiber technology: current status and emerging developments. Progress in polymer science, 2017, 70: 1-17.

- Katsnelson, M. (2014). Nanofiber fabrics could keep soldiers warm and dry. Nature.

- Liu, Y., Wang, Z., Liu, Q., & Wu, H. (2012). Facile preparation of antibacterial and hydrophobic surface on cotton fabrics by in situ polymerization of silica nanoparticles and fluorinated monomers. Journal of Colloid and Interface Science, 369(1), 142-149.

- Liu, Y., Wang, Z., Liu, Q., & Wu, H. (2013). Super-hydrophobic and antibacterial cotton fabric modified by silica nanoparticles and lauric acid. Carbohydrate Polymers, 92(1), 59-65.

- Barhoum, A., Van Assche, G., De Clerck, K., & Rahier, H. (2012). Review: current progress in the production of electrospun nanofibres for tissue engineering applications. Journal of Materials Science, 47(16), 7153-7170.

- Xie, L., Zuo, L., Zhang, W., & Liu, Y. (2017). Review: recent progress in electrospun nanofibers for wound healing applications. Journal of Nanomaterials, 2017, 1-10.

- Wei, L., Lu, H., & Wu, S. (2013). Facile fabrication of superhydrophobic surfaces with excellent self-cleaning properties by controlling the morphology of nanostructures on electrospun fibers. Journal of Materials Science, 48(21), 7508-7516.

- Kumar, S., Anjali, S., Singh, R., & Bandyopadhyay, S. (2019). Polysaccharide-based nanofibers for biomedical applications: A review. Carbohydrate Polymers, 225, 115228.

- Zhu, Y., Zhang, X., Zhou, G., Lu, L., Xu, J., & Jin, W. (2017). Preparation of photochromic PVA/TiO2 nanofiber membranes via electrospinning. Journal of Applied Polymer Science, 134(3), 1-9.

- ZHOU, Yangjian, et al. Electrospun nanofiber membranes for air filtration: A review. Nanomaterials, 2022, 12.7: 1077.

- Sahoo, S. K., Tripathy, J., & Manna, J. (2018). Textile-based smart wound dressings. Current Trends in Textile Science & Technology, 4(1), 1-7.

- LI, Tao; SUN, Mingchao; WU, Shaohua. State-of-the-art review of electrospun gelatin-based nanofiber dressings for wound healing applications. Nanomaterials, 2022, 12.5: 784